- Home

- Manual Torque Wrench

- 62 Industrial Torque Wrench

- 62 Adjustable Torque Wrench

- 62 Adjustable Torque Wrench

62 Adjustable Torque Wrench

Product Introduction

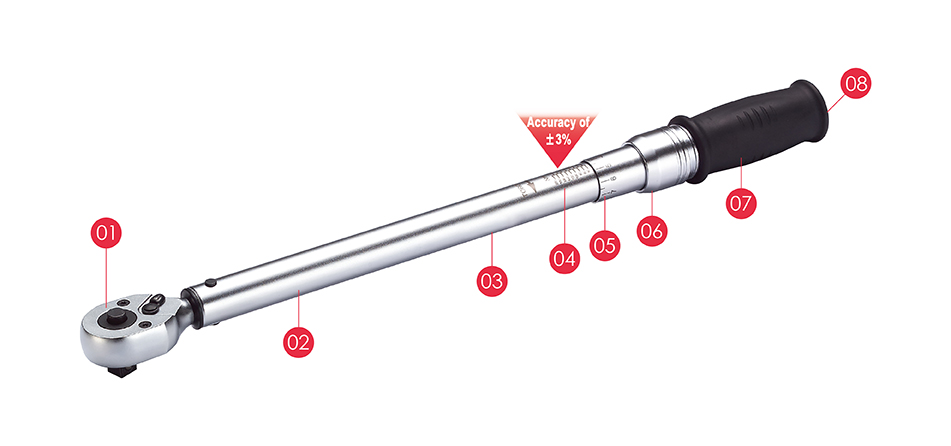

- Ratchet head: A highly robust ratchet mechanism for CW and CCW directions application. Quick released design for changing socket quickly. Repair kit for inner spare parts of ratchet head is available.

- Reliable mechanism: The robust and resistant fully chromed steel tube is ideal of industrial use. An audible and palpable signal indicates automatically when the desire torque value is achieved.

- Serial number: Each piece stamping serial number for traceability.

- Scales: Easy read laser scales is flexible for multi units and double scales for different market need.

- Micrometer scales: Very precise adjustment by visible micrometer laser scales on handle ensure optimal and simplified readings while operation.The micrometer scales for precision adjustment is in integral values, for user easily take round figure while operation.

- Lock ring: Easy torque adjustment by press down the Lock-ring, brings energy saving and automatically lock device to avoid accidentally altering setting.

- TPR handle: The injection method TPR handle with non-slip and comfort features. REACH - SVHC Declaration of Conformity.

- End cap:Plastic poly end cap with standard or customized design.

| TT NO. | Square drive | Teeth | Nm | Graduation | L(mm) | g | case/CTN |

|---|---|---|---|---|---|---|---|

| TW-262-1DW | 1/4” | 24T | 2~10 | 0.1 | 281 | 590 | 24 |

| TW-262-2DW | 4~20 | 0.1 | 329 | 650 | 24 | ||

| TW-262-4DW | 10~50 | 0.25 | 329 | 650 | 24 | ||

| TW-262-8DW | 5~25 | 0.2 | 329 | 650 | 24 | ||

| TW-362-1DW | 3/8” | 24T | 4~20 | 0.1 | 329 | 650 | 24 |

| TW-362-2DW | 32T | 20~100 | 0.5 | 436 | 1320 | 12 | |

| TW-362-3DW | 10~60 | 0.5 | 344 | 760 | 24 | ||

| TW-362-4DW | 10~50 | 0.25 | 344 | 760 | 24 | ||

| TW-362-8DW | 24T | 5~25 | 0.2 | 329 | 650 | 24 | |

| TW-362-9DW | 2~10 | 0.1 | 281 | 590 | 24 | ||

| TW-462-1DW | 1/2” | 32T | 40~200 | 1.0 | 512 | 1580 | 12 |

| TW-462-2DW | 60~340 | 2.0 | 614 | 1800 | 12 | ||

| TW-462-3DW | 60~420 | 2.0 | 614 | 1800 | 12 | ||

| TW-462-5DW | 80~400 | 2.0 | 614 | 1800 | 12 | ||

| TW-462-8DW | 50~350 | 2.0 | 614 | 1800 | 12 | ||

| TW-462-84W | 20~100 | 0.5 | 436 | 1310 | 12 | ||

| TW-662-1DW | 3/4” | 24T | 100~600 | 5.0 | 1050 | 5030 | 2 |

| TW-662-2DW | 150~800 | 5.0 | 1240 | 6110 | 2 | ||

| TW-662-3DW | 200~1000 | 5.0 | 1240 | 6110 | 2 | ||

| TW-662-5DW | 32T | 80~400 | 2.0 | 614 | 1800 | 12 | |

| TW-862-1DW | 1” | 24T | 150~800 | 5.0 | 1240 | 6230 | 2 |

| TW-862-2DW | 200~1000 | 5.0 | 1240 | 6110 | 2 | ||

| TW-862-3DW | 300~1500 | 10 | 1850 | 10510 | 1 |

| TT NO. | Square drive | Teeth | ft~lb (in~lb) | Graduation | L(mm) | g | case/CTN |

|---|---|---|---|---|---|---|---|

| TW-262-1EW | 1/4” | 24T | 20~100 | 1.0 | 281 | 590 | 24 |

| TW-262-2EW | 30~200 | 1.0 | 329 | 650 | 24 | ||

| TW-262-6EW | 100~500 | 2.5 | 329 | 650 | 24 | ||

| TW-262-7EW | 50~250 | 2.0 | 329 | 650 | 24 | ||

| TW-362-1EW | 3/8” | 24T | 30~200 | 1.0 | 329 | 650 | 24 |

| TW-362-2EW | 32T | 10~80 | 0.5 | 436 | 1320 | 12 | |

| TW-462-1EW | 1/2” | 32T | 20~150 | 1.0 | 512 | 1580 | 12 |

| TW-462-2EW | 30~250 | 1.0 | 614 | 1800 | 12 | ||

| TW-442-8EW | 10~80 | 0.5 | 436 | 1320 | 12 | ||

| TW-662-1EW | 3/4” | 24T | 50~450 | 5.0 | 1050 | 5030 | 2 |

| TW-662-2EW | 100~600 | 5.0 | 1240 | 6110 | 2 | ||

| TW-662-3EW | 150~750 | 5.0 | 1240 | 6110 | 2 | ||

| TW-642-4EW | 32T | 60~300 | 2.0 | 614 | 1800 | 12 | |

| TW-862-1EW | 1” | 24T | 100~600 | 5.0 | 1240 | 6230 | 2 |

| TW-862-2EW | 150~750 | 5.0 | 1240 | 6110 | 2 | ||

| TW-862-3EW | 200~1000 | 5.0 | 1850 | 10510 | 1 |